Ysterhout Dot Net

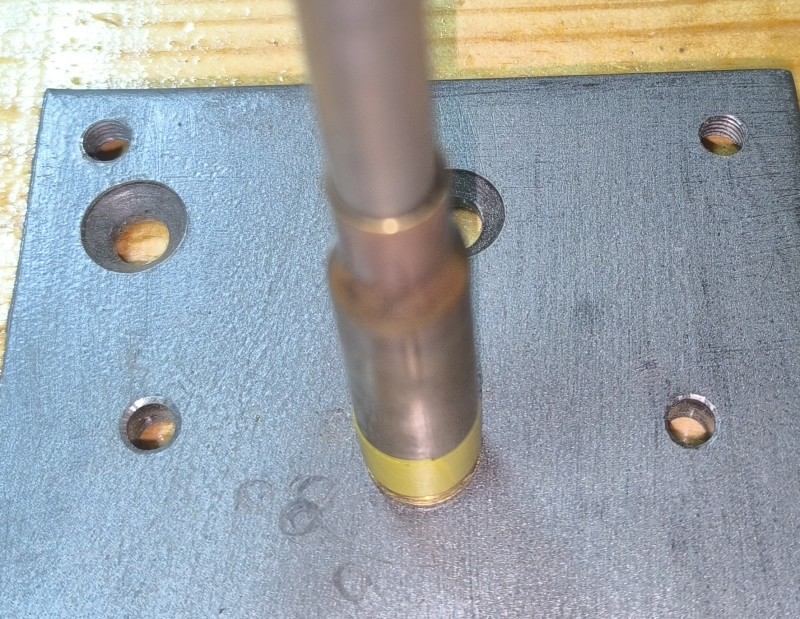

A metal plate to work on, and a length of half inch bar bar that has a protrusion machined at the end to center inside the BMG flash hole. Two long pin punches, sizes 1/8 and 3/8 inch , and a small hammer.

The bushing needs to be fitted. This is simply done.

Place the bushing on the plate, center the primer pocket over the bushing, fit the protrusion into the flash hole through the case mouth , and tap the rod with a very light hammer. It doesn't take force, it's a press fit. It also doesn't back out on ignition. If you insert it upside down, you can easily remove it with the correct size pin punch.

Once the bushing is in the case, you can't use a conventional BMG decapping die to decap the spent primer - the flash hole is too small. I had a decapping rod from an old die that was long enough, and I fixed a nut on it so I could use a small hammer on it to decap. or a correct size long pin punch will also do.

A large nut to raise the fired case, so the popped primer has somewhere to go.

A roll pin punch of the correct diameter can be used to remove the bushing from spent brass, and re-inserted into a fresh case, so the inserts are re-usable.

It's necessary to uniform the BMG pocket and apply the crimp removal tool to the primer pocket, to clean it up and give the mouth of the pocket a slight bevel, which facilitates the insertion of the bushing.

I made this little gadget, the paper circle is impaled on the pointy end, then inserted to the depth marked by the yellow tape. The tube is held in place, and the pointy bit withdrawn to the next tape mark.

This leaves the paper circle nicely in the bottom of the case on top of the priming charge.